Analyzing the advantages of Yingyi PS series planetary gearboxes

Release time:

2018-12-08

Yingyi utilizes 3D design and analysis technology to trim the helical tooth surface for tooth shape and guide respectively, in order to reduce the impact and noise of gears on meshing and meshing out, and to increase the service life of the gear train. The gear material is made of high grade chrome molybdenum alloy steel, and the gear center hardness is tempered to 30HRc to obtain the best wear resistance and impact toughness. Reduction mechanism adopts helical gear design, its tooth meshing rate is generally more than two times of spur gears, with smooth running, low noise, high output torque and low backlash characteristics Yingyi transmission will be the sun gear bearings directly mounted in the planetary armature, to improve the operating accuracy of the gear train; input and motor of the

Yingyi utilizes 3D design and analysis technology to trim the helical tooth surface for tooth shape and guide respectively, in order to reduce the impact and noise of gears on meshing and meshing out, and to increase the service life of the gear train. Gear material selection of high-grade chrome-molybdenum alloy steel, gear center hardness tempered to 30HRc, has been obtained to improve the wear resistance and impact toughness. The reduction mechanism adopts helical gear design, whose tooth meshing rate is more than two times of the general spur gear, which has the characteristics of smooth running, low noise, high output torque and low backlash.

Yingyi Transmission installs the bearings of the sun gears directly in the planetary arm to improve the running accuracy of the gear system; the connection between the input end and the motor adopts a simple clamp-type locking mechanism and undergoes a dynamic balance analysis to ensure the concentricity of the combined interface and the transmission of the power with zero backlash under the high input speed; the planetary arm and the output shaft adopt the one-piece structural design, and the bearing configuration of the output shaft adopts the large span design to ensure the greatest torsional rigidity and the output load capacity. The bearing configuration of the output shaft adopts large span design to ensure the greatest torsional rigidity and output load capacity.

Single-stage planetary speed reducer: Model: PS060, PS090, PS120, PS150

Ratios: 3, 4, 5, 7, 10

Double-stage planetary speed reducer: Model: PS060, PS060A, PS090, PA090A, PS120, PS150

Reduction ratio: 15, 20, 25, 30, 35, 40, 50, 70, 100

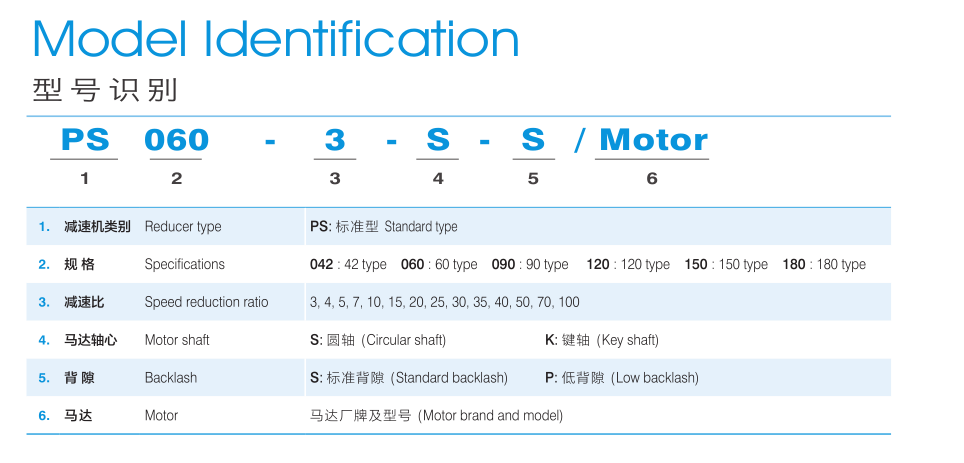

Planetary reducer model description:

Reducer selection table:

Related News